-40%

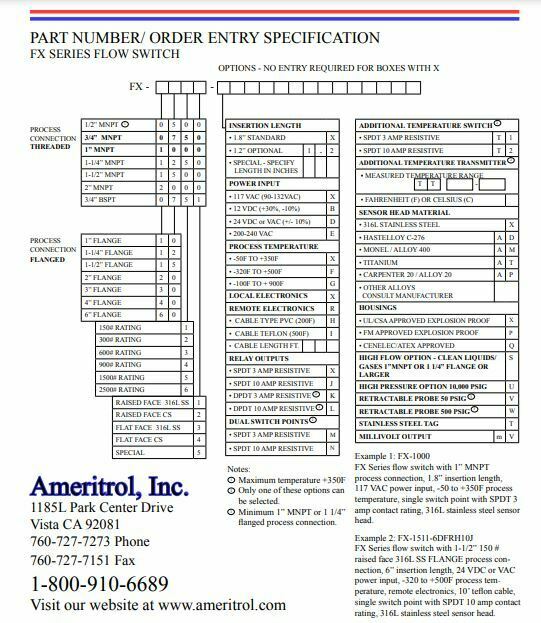

AMERITROL FX-0750 Explosion Proof 3/4" NPT Flow Switch 1500PSI Rated 3A 120V NOS

$ 158.4

- Description

- Size Guide

Description

AMERITROL FX-0750, FX0750 Explosion Proof 3/4" NPT Flow Switch 1500PSI Rated 3A 120V 1-Pc. NOS!!************************************************ FREE SHIPPING!! *************************************

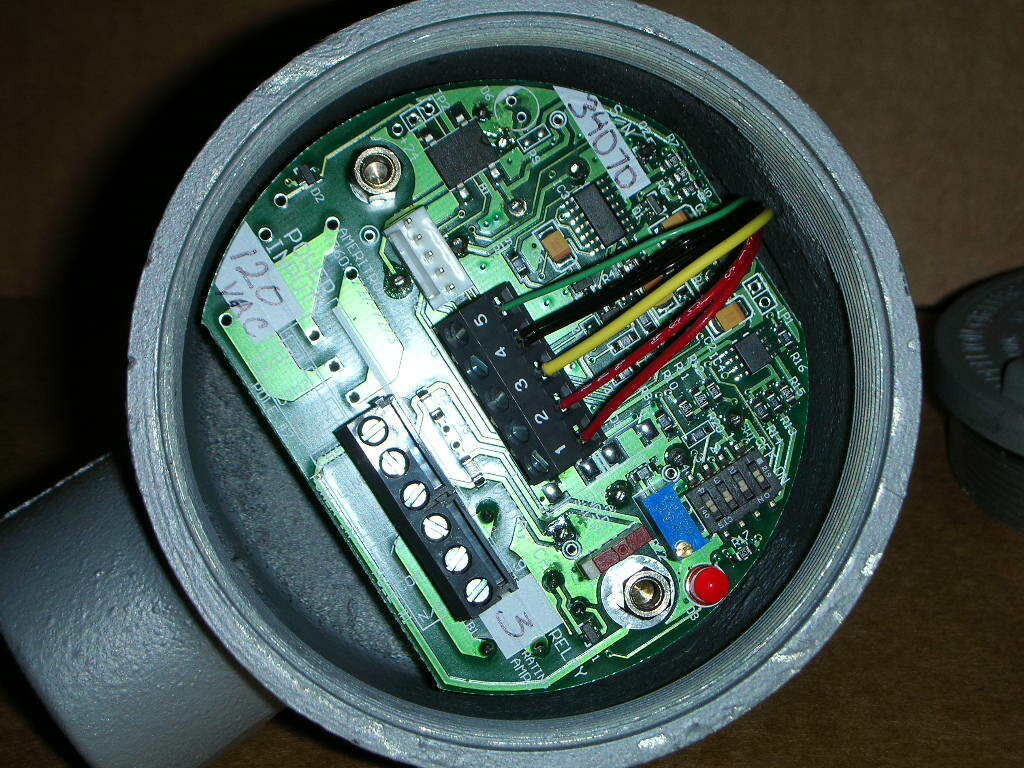

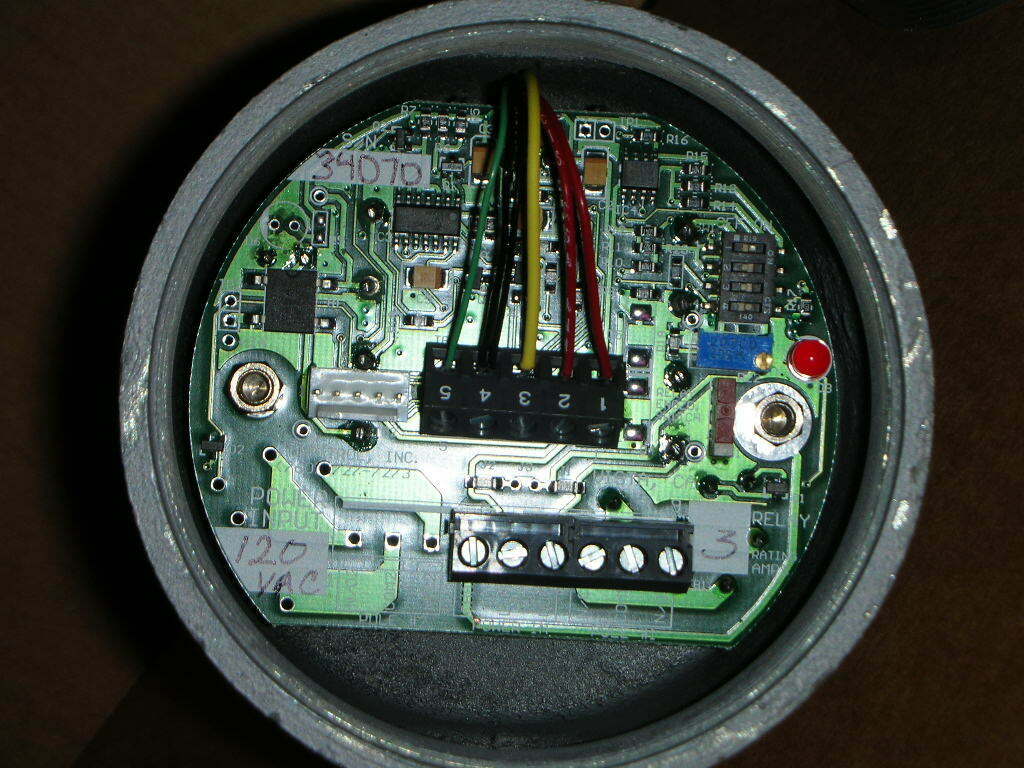

New Old Stock (NOS). Purchased in bulk therefore no original packaging. Items were repackaged and relabeled. See pictures for actual condition.

Sold as 1-piece (each).

This is an AMERITROL model FX-0750 Explosion Proof Flow Switch, The switch has a 3/4" NPT connection and is rated for 1500PSI. The output relay is a Single Pole Double Throw (SPDT) configuration with a 3 Amp Resistive load rating. The switch is powered by a standard 120VAC power source. This has the standard 1.8" insertion length (probe length from the bottom of the threads).

This listing is for ONE (1) AMERITROL FX-0750 Explosion Proof 3/4" NPT Flow Switch. Sold as 1-piece (each).

Thanks for looking!!

From the manufacturer:

The FX series flow switch is the most reliable flow switch available. The thermal dispersion principle of operation features no moving parts and provides an extremely reliable and repeatable switch for the most demanding industrial applications. The sensor head employs two temperature sensors with a constant very low power heating source physically attached to one of the temperature sensors. The second temperature sensor is isolated from the heating source and provides compensation for changing process temperatures. As flow changes so does the temperature differential. This allows the device to be used as a flow/no flow sensor and to be used to switch at any velocity shown in the flow switch range chart. Extremely low flow rates can be detected with rangeability up to 300:1.

These devices are ideal for use in virtually all liquids, gases, and slurries. With no moving parts exposed to the process end users are provided an extremely reliable and repeatable instrument even in viscous or corrosive applications. The electronics are available with single or dual switch points. Temperature monitoring is also available with either a switch output or a linear 4-20 mA output. Relay outputs are standard and are offered with several different configurations and contact ratings. Remote mounting of the electronics is also available.

Features

• No Moving Parts

• 316L Stainless Steel Sensor

• Temperatures to 900F

• Pressures to 10,000 PSIG

• Simple and Easy Field Calibration

• Explosion Proof Enclosures

• Low Flow Rate Detection

• Threaded, Flanged, Retractable Probes

• Exotic Alloys for Corrosion Resistance

• Field Programmable for Relay Energization

Specifications:

Sensor Head

Material of 316L Stainless Steel Standard

Operating -50 to +350F (-46 to +177C) Standard

Pressure: Vacuum to 1500PSI

Response Time: From 3 Seconds

Repeatability: ± 0.5% of Range at Constant Conditions

Process ¾” MNPT, 1” MNPT Standard

Connection: Option Flanged, Retractable Probes,

and ½”, 1-¼”, 1-½”, 2” MNPT

Probe Length: 1.8”

Electronics:

Housing: Explosion Proof,

Nema 4X, UL/CSA Rated to Class 1,

Div. 1 & 2, Group B,C,D; Class II, Div.

1 & 2, Group E,F,G; Class III.

Option FM and Cenelec/ATEX

Temperature: -50 to +150F (-46 to +65C)

Power Input: 120 VAC, 50/60 Hz, 4 Watts; Options:

12 VDC, 24 VDC/VAC, 240VAC

Relay Output: SPDT 3 Amps Resistive Standard

Electrical:

Connection: 1” FNPT

Shipping:

Weight: 5 lbs

APPLICATIONS

Pump Protection:

The FX series flow switch can reliably shut down pumps on low or no flow

Bearing Lubrication:

Detects loss of lubricant flow

Seal Leakage:

Switch verifies positive seal flow or detects excessive leakage indicating maintenance requirement

Chemical Feed and Metering Pumps:

Indicates low or no flow of chemical additives to process fluids down to .02 feet/sec

Safety Shower and Eye Wash Station:

The FX series switch detects high flows from a safety shower and the low flows of an eye wash station. It can be wired to sound an alarm, turn on an emergency light, and/or send a signal to the control room for emergency help.

Analyzer/ Gas Chromatographs:

Confirms continuous sample flow to instruments

Control Rooms:

A flow switch can be used for monitoring of plant equipment such as pumps, valves, and fans, providing a contact closure when the process condition changes.

Purge Air:

Detects or verifies flow to meet plant safety requirements

Spray Nozzles:

A flow switch can reliably detect nozzle blockage in coating applications

Relief Valve/Rupture Disks:

The FX switch can provide automated detection of flow or leakage of safety relief valves or rupture disks

Chiller Lines:

Automatic shut down of chillers on low or no flow

Heater Burnout Prevention:

The FX series flow switch can initiate heater shutdown on loss of flow to prevent overheating of elements

Tank Car Loading:

The FX senses dry line or phase change from liquid to nitrogen gas flow

Drain Line Sensor:

Capable of detecting low flow in partially filled lines

Agitation Monitor:

Provides positive indication of agitation in tanks, vessels, or ponds

Flare Stack Monitor:

The FX series no moving parts thermal dispersion flow switch is ideal for monitoring dirty gases in flare stack applications